TOP ENTRY

KF TYPE

-

Features

It is simple to construct and easy to assemble and install, using a hollow shaft reducer.

The height of the drive unit can be minimized by using the horizontal reducer.

Depending on the pressure and temperature conditions of the Vessel, it can be equipped with Lip Seal, Gland Packing, or Mechanical Seal.

The RPM can be selected based on the specifications of the reducer used, and you can use the inverter and the transmission to obtain the required number of revolutions.

Based on the on-site conditions, motor, such as Flameproof, Increased Safety, and general motor, can be installed.

The wetted parts can be made of various materials such as STS304, STS316L, HASTELLOY-C, TITANIUM, or LINING(RUBBER.FRP.TEFLON), depending on the contents.

Various types of impellers can be installed depending on the mixing purpose

KR TYPE

-

Features

It is suitable for use as a reactor in medium to large-sized, high-viscosity, and low-viscosity close vessel applications.

The RPM can be selected based on the specifications of the reducer used, and you can use the inverter and the transmission to obtain the required number of revolutions.

Depending on the pressure and temperature conditions of the Vessel, it can be equipped with Lip Seal, Gland Packing, or Mechanical Seal.

Based on the on-site conditions, motor, such as Flameproof, Increased Safety, and general motor, can be installed

The wetted parts can be made of various materials such as STS304, STS316L, HASTELLOY-C, TITANIUM, or LINING(RUBBER.FRP.TEFLON), depending on the contents.

Various types of impellers can be installed depending on the mixing purpose.

KET TYPE-A

-

Features

It is suitable for use as a reactor in medium to large-sized, high-viscosity, and low-viscosity close vessel applications.

The RPM can be selected based on the specifications of the reducer used, and you can use the inverter and the transmission to obtain the required number of revolutions.

Depending on the pressure and temperature conditions of the Vessel, it can be equipped with Lip Seal, Gland Packing, or Mechanical Seal

Based on the on-site conditions, motor, such as Flameproof, Increased Safety, and general motor, can be installed

The wetted parts can be made of various materials such as STS304, STS316L, HASTELLOY-C, TITANIUM, or LINING(RUBBER.FRP.TEFLON), depending on the contents.

Various types of impellers can be installed depending on the mixing purpose.

KET TYPE-B

-

Features

It saves time for inspection and replacement because the Mechanical Seal can be easily replaced without swinging the reducer to disassemble it

It is suitable for use as a reactor in medium to large-sized, high-viscosity, and low-viscosity close vessel applications

The RPM can be selected based on the specifications of the reducer used, and you can use the inverter and the transmission to obtain the required number of revolutions

Depending on the pressure and temperature conditions of the Vessel, it can be equipped with Lip Seal, Gland Packing, or Mechanical Seal.

Based on the on-site conditions, motor, such as Flameproof, Increased Safety, and general motor, can be installed.

The wetted parts can be made of various materials such as STS304, STS316L, HASTELLOY-C, TITANIUM, or LINING(RUBBER.FRP.TEFLON), depending on the contents.

Various types of impellers can be installed depending on the mixing purpose.

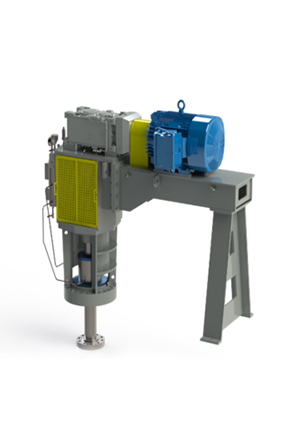

KE TYPE

-

Features

It is easy to replace the mechanical seal without disassembling the agitator for easy maintenance.

The height of the drive unit can be minimized by using the horizontal reducer.

It is suitable for use as a reactor in medium to large-sized, high-viscosity, and low-viscosity close vessel applications.

The RPM can be selected based on the specifications of the reducer used, and you can use the inverter and the transmission to obtain the required number of revolutions.

Depending on the pressure and temperature conditions of the Vessel, it can be equipped with Lip Seal, Gland Packing, or Mechanical Seal.

Based on the on-site conditions, motor, such as Flameproof, Increased Safety, and general motor, can be installed.

The wetted parts can be made of various materials such as STS304, STS316L, HASTELLOY-C, TITANIUM, or LINING(RUBBER.FRP.TEFLON), depending on the contents.

Various types of impellers can be installed depending on the mixing purpose.